19 MM Drilling Machine

Product Details:

- Condition NEW

- Spindle Speed 1440 RPM

- Product Type DRILL MACHINE

- Material CASTING

- Computerized No

- Automatic Grade Semi-Automatic

- CNC Or Not Normal

- Click to View more

X

19 MM Drilling Machine Price And Quantity

- 1 Unit

19 MM Drilling Machine Product Specifications

- GREEN

- Semi-Automatic

- CASTING

- 1440 RPM

- 220 Watt (w)

- 50 Kilograms (kg)

- No

- DRILL MACHINE

- 3 PHASE Watt (w)

- Normal

- NEW

19 MM Drilling Machine Trade Information

- Bhavnagar , Gujarat

- 2-3 Days

- Contact us for information regarding our sample policy

- Plastic Cover, Hard Paper & Wooden Box Packing

- All India

- ISO 9001 : 2008

Product Description

SPECIFICATION

| Drilling Machine | 19 mm |

| Tapping Machine Capacity | 19 mm. |

| Drilling Capacity | 19 mm. |

| Spindle Travel/Table travel (6 mm.) | 125 mm. |

| Distance Spindle to Column | 200 mm. |

| Distance between chuck to base | 750 mm. |

| Distance between chuck to work table | 630 mm. |

| Size of base Plate-L x B | 430 x 280 mm. |

| Size of Work Table-L x B | 265 x 265 mm. |

| Diameter of Column | 74mm. |

| V-Belt (Inside) | - |

| V-Belt for Motor (Outside) | B-35 |

| No. of Spindle Speeds | 8 |

| Forwards Speeds Range | 80 to 3300 |

| Reverse Speeds Range | 80 to 3300 |

| Motor Single phase or three phase | 0.5 H.P. |

| | 1440 R.P.M. |

| gear Motor H.P. & R.P.M.(SinglePhase) | 0.25 H.P. & 20 R.P.M. |

| Overall Height | 1345 mm. |

Enter Buying Requirement Details

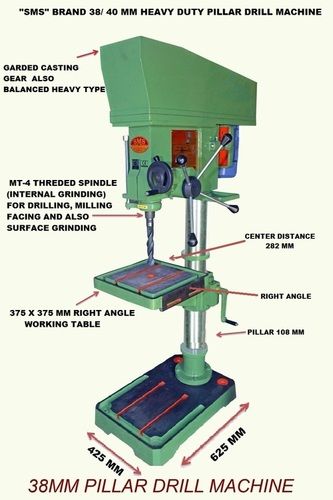

Other Products in 'Pillar Drill Machine' category

"We are accepting only bulk quantity orders."

GST : 24BEZPS7292J1ZE

Vadava Talawadi, Bhalvado Kancho, Bhavnagar - 364001, Gujarat, India

Phone :08061034998

|

|

SIDDHAPURA MANUFACTURER & SUPPLIERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |